20 March 2025

Enzyme production quality, functionality and performance

Recombinant enzymes are a viable and more effective alternative to natural enzymes for many scientific applications. However, they must be produced in a carefully controlled environment to achieve the right characteristics for this purpose. Therefore, it’s essential that enzyme manufacturers curate ideal conditions and maintain high standards for their enzyme production process.

Our CrisBio® technology has been developed over decades to ensure these standards. In this blog, we explore how our enzyme production process ensures the highest levels of quality and performance for all recombinant enzymes manufactured.

Making enzyme-powered research possible

At Cocoon Bioscience, we support life sciences researchers exploring alternative techniques and innovative enzyme use cases to accelerate their progress.

Our platform is optimized to express complex and customized enzymes that others cannot, as well as to deliver a range of classes of enzymes rapidly, affordably and at scale. We can support you through the proof-of-concept stage to the commercial application phase.

Combining our novel expression process, and a new industrial enzymes facility, Cocoon Bioscience delivers manufacturing excellence that meets the stringent requirements of these applications.

View Thermostable Inorganic Pyrophosphatase

Our enzyme production method

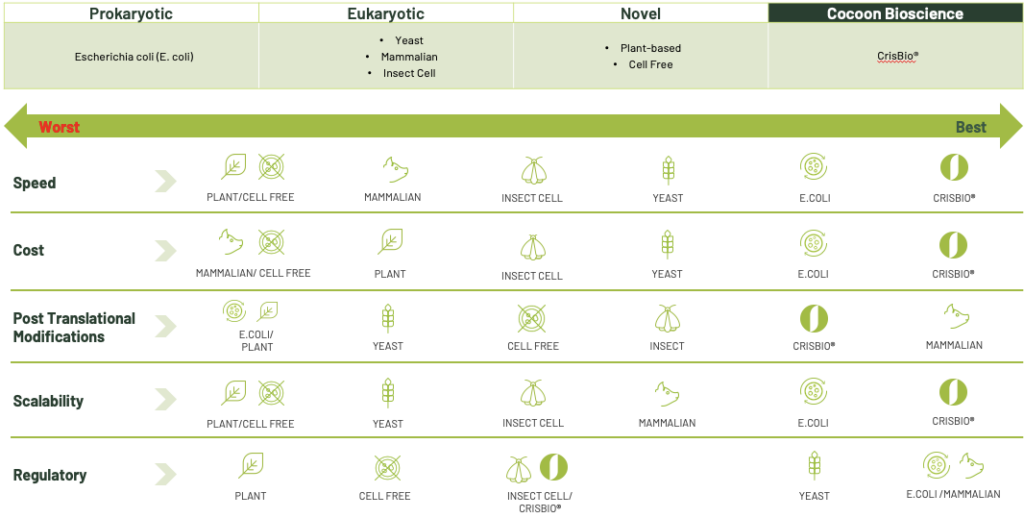

What sets CrisBio® apart? CrisBio® leverages the power of nature to optimize the BEVs system for complex enzyme expression. By inoculating a living insect versus cultivated cells, we create a more ideal environment for successful expression than traditional bio-fermentation processes.

Here’s an example of a product produced with CrisBio®

Pyrophosphatase is a representative example of the category of enzymes we work on. It’s commonly used in mRNA production to cleave off phosphate groups.

Traditionally, this enzyme is costly to produce at R&D and manufacturing scales. This inevitably creates an expensive final product, which is a significant barrier to the progress of important life sciences development. Our product breaks down this barrier.

Our state-of-the-art CrisBio® platform is incredibly productive for the expression of pyrophosphatase. As such, we produce thermostable inorganic pyrophosphatase at a fraction of the price compared to other recombinant protein expression systems.

Delivering you the best product

Our process is curated to deliver the highest quality products for specific applications. This involves optimizing many parameters, from the expression host to the downstream quality assurance process. Here is how we ensure the best outcomes at every stage:

The perfect environment

The cocoon as a natural bioreactor

The cocoon stage of the Trichoplusia ni provides the optimal conditions for enzymes to express. Plus, the insect naturally possesses biological functions that support successful expression (even in complex cases).

Environmental factors

Environmental factors like pH and temperature are naturally easy to control thanks to the host cocoon. Nevertheless, our labs are carefully curated to provide the optimal conditions.

Enzyme functionality

As a result of our carefully designed enzyme production process, we achieve high levels of functionality, yield and performance that match commercial gold standards.

Controlled processes

The multicellular cocoon environment is well-designed to handle complex folding and post-translational modifications that are necessary for many enzymes. Additionally, our Upstream process is defined specifically for every enzyme, including virus dose, time of incubation and temperature.

Expert input

Throughout the entire production process, our team of scientists provide expert guidance, troubleshoot issues and optimize to ensure you get the most optimal output.

Enzyme quality control

Enzyme quality is of the utmost importance to us, because we know it is to you. We monitor several factors and perform rigorous quality control testing to deliver high-quality products suitable for the life sciences industry.

Protein identity

The identity of the recombinant protein is confirmed using Western blotting. This approach not only validates the correct expression of the protein but also ensures that it maintains its expected structural and functional characteristics.

Enzyme activity

Activity is quantified using a test designed and validated specifically for each enzyme. Reliable methods like spectrophotometry allows us to precisely monitor enzyme kinetics. This gives us valuable insights into the enzyme’s functionality, substrate interaction, and optimal conditions for activity.

Protein purity

The CrisBio® process generates the recombinant protein within a solid mass. To extract this protein, we mill and filter the product to produce a liquid extract that then follows a conventional downstream purification process. Finally, the purity is evaluated by SDS-PAGE, Coomassie staining and densitometry.

Concentration

We measure concentration using densitometry in mg/ml. This enables us to accurately evaluate the specific activity of the product, providing insight into its efficacy and performance.

Residual nucleases and residual gDNA

To ensure the purity of our product, we evaluate the presence of any residual nucleases and genomic DNA after the purification process. This assessment is crucial for minimizing these contaminants to the lowest possible levels, thereby enhancing the quality and reliability of the final product.

Stability

The shelf life of our proteins is determined through rigorous stability testing. These tests are designed to simulate various storage conditions and environmental factors, allowing us to accurately predict the shelf life and stability of our proteins under different circumstances.

Prior to analyzing any final product, all quality assessments undergo thorough validation to ensure their reliability and accuracy. Altogether, our quality control process guarantees that we consistently deliver products of the highest standard.

Output scalability

We can accommodate small or large-scale production thanks to our scalable platform. The size and larger biomass of a multi-cellular system means we can scale quickly, while maintaining consistent quality. Plus, our synchronized rearing process means we can automate this at scale (which reduces your costs).

- Proof-of-concept – micrograms, milligrams or grams

- Development & scaling – grams and kilograms

- Final product – scale output based on your needs, such as RUO or adhering to GMP

Enzyme customization

Every project is unique, and a one-size-fits all approach isn’t the only way we work. That’s why we also offer bespoke, custom enzyme solutions.

But what makes CrisBio® so suitable for enzyme customization? The speed and flexibility of our platform makes it easy to test, reiterate and progress your research.

Rapid proof-of-concept development

Flexible modifications ![]()

Cost-effectiveness

Explore custom enzyme development

Advocates of enzyme R&D

We are invested in your innovations. Our aim has always been to make life sciences innovation more accessible and achievable. This meant spending two decades refining a platform to address common bottlenecks in recombinant protein production. Moreover, it means continuing to explore ways to improve upon our own methods.